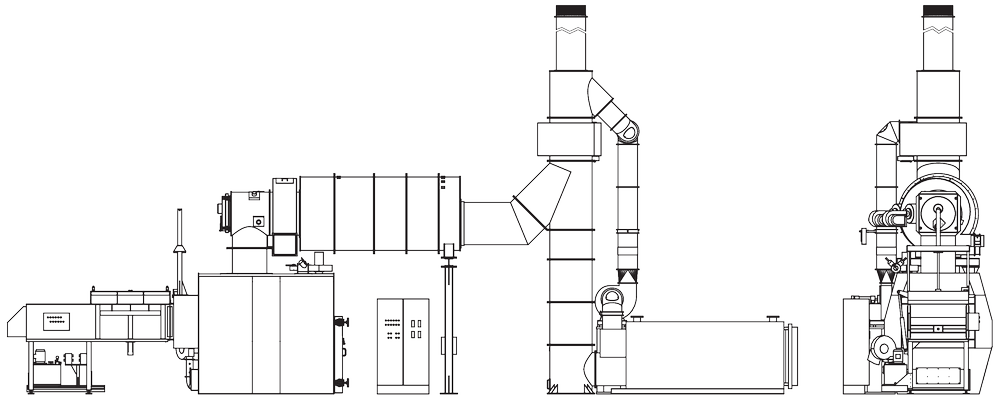

ProductsWe produce complete technology of the CV and GG incinerators:

|

|

Mechanical parts of incinerators are made in the Czech Republic. Measurement, control and visualization are made in Austria. The CV and GG incinerators are approved for operation in the CZ. |

|

Incinerators are produced in several basic sizes with a daily capacity of incinerated waste from 300 kilograms to 8 tons. The product line reflects the common needs of hospitals and industrial plants.

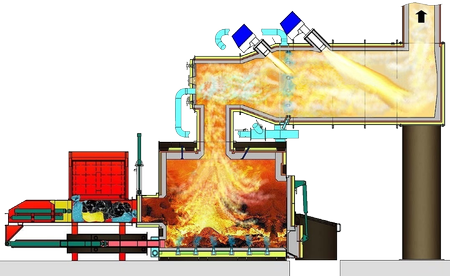

Operation is fully automatic, with the possibility of semi-manual control. Incinerators use a multi-stage multi-zone combustion method. Thermal decomposition and combustion are temporally and spatially separated, but above all independently regulated processes. Individual monitoring and control of each operation gives good incineration performance, virtually independent of the waste composition, with smoke free operation and uncontaminated gas emission. Design of the thermal reactors allows to adjust the residence time of the flue gases and thus adapt the incinerator to the required amount and type of incinerated waste. The thermal reactor can be oriented as needed to achieve the desired spatial arrangement. Feeders for combustion chambers we produce in several modifications:

|

| model | CV 1 | CV 2 | GG 7 | GG 14 | GG 24 | GG 42 |

| performance | ||||||

| amount of waste [kg/day] 1) | 300 | 500 | 1.200 | 2.500 | 4.500 | 8.000 |

| feeding time [h/day] | 8 | |||||

| max. energy input [kW] | 140 | 275 | 740 | 1.400 | 2.400 | 4.200 |

| max. thermal power [kW] 2) | 100 | 190 | 400 | 840 | 1.450 | 2.500 |

| electric power [kW] 3) | – | – | 40 | 80 | 140 | 250 |

| thermal power [kW] 3) | – | – | 340 | 710 | 1.230 | 2.100 |

| incineration | ||||||

| charging chamber volume [m3] | – | – | 0,5 | 0,9 | 1,9 | 3,1 |

| combustion chamber volume [m3] | 0,9 | 1,9 | 2,4 | 6,3 | 10,8 | 17,0 |

| incineration temperature [°C] | 600 ÷ 900 | |||||

| post combustion temperature [°C] | 900 ÷ 1.400 | |||||

| residence time in the thermal reactor [s] | 0,5 ÷ 2 | |||||

| consumption (data are based on operational experience and depend very much on waste properties) | ||||||

| fuel - natural gas [m3/kg of waste] | 0,1 ÷ 0,2 | |||||

| alternative fuel - LFO [kg/kg of waste] | 0,08 ÷ 0,16 | |||||

| adsorbent [kg/hour] | 3,5 | 5 | 9 | 16 | 26 | 40 |

| 1) average calorific value of waste 15 MJ/kg | ||||||

| 2) with hot water exchanger 90/70°C | ||||||

| 3) combined heat and power generation with hot water exchanger 90/70°C | ||||||

| clean gas - at 11 % O2 | ||||

| dust | < 10 mg/Nm3 | Hg | < 0,05 mg/Nm3 | |

| HCL | < 20 mg/Nm3 | dioxin / furan / TE | < 0,1 mg/Nm3 | |

| SO2 | < 50 mg/Nm3 | Cd, Ti | < 0,05 mg/Nm3 | |

| HF | < 2 mg/Nm3 | Pb, Cr, Cn, Sn, V, Mn, Sb | < 1,0 mg/Nm3 | |

| NOx | < 250 mg/Nm3 | As, Se, Ni, Co, Te | < 1,0 mg/Nm3 | |

| 4) flue gas cleaning principle consists in their reaction with suitable additives which chemically bind the acidic components (HCl, HF, SO) and organic compounds (expressed as total carbon C and PCDD/F). Waste products from flue gas cleaning are captured on fabric filters. Emissions are monitored continuously. | ||||

HW INCINERATOR |